|

Oriented Wire

Shield and Seal

This composite gasketing

material is designed for use in suppressing

EMI/RFI while at the same time providing an

effective, full pressure, environmental

seal between mating surfaces. It is

comprised of conductive wires oriented

perpendicular to the mating surfaces and

embedded in sponge

or solid silicone elastomer . It

is recommended for use in both military and

commercial applications that require high

levels of EMI/RFI shielding over a wide range of

temperatures and environmental conditions |

|

|

Elastomer

gasketing with conductive suspended wires

provides EMI/RFI shielding with

full pressure seal

Oriented Wire Shield

and Seal is a highly conductive composite

shielding material consisting of sponge or soild

silicone elastomer in which oriented - monel or aluminum wires are

chemically vulcanized into the elastomer.

These embedded wires are strategically constructed to provide more than 900 physical

contact points per square inch with mating metallic surfaces. The silicone elastomer stabilizes each individual conductive wire even under the most severe

compressive loading. The silicone provides resilience

that assures effective sealing even where the mating

surfaces are largely uneven. It also prevents moisture, even water, from penetrating through or

around critical gasket/equipment interfaces.

Dependable

shielding in extreme

environments

Oriented Wire Shield and Seal gaskets will withstand a wide range of

temperature extremes (-65 to 200 Celsius) and the most severe environmental conditions

while providing a metal-to-metal conductive path. Among

their many features are minimal compression set

with corresponding wideband shielding

effectiveness.

Materials

and gasket forms for all

applications

Oriented Wire Shield and Seal gasketing is available in sheet, strip or ring

form. Standard conductive media is Monel or Aluminum wires. Pressure sensitive

adhesive backings are available where required for ease of installation. Fluorosilicone compounds are also available for applications involving contact

with chemical solutions or silicone oils.

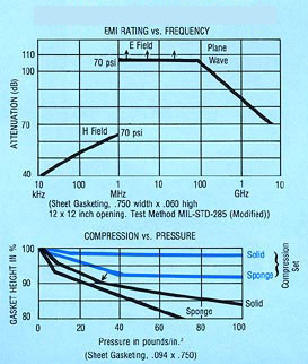

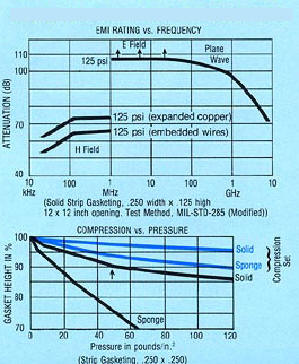

Typical Shielding Performance:

|

Sheet Gasketing

In

solid or sponge type silicone.

Standard widths from 3" to 9"

(76.20 to

228.60 mm).

Standard thicknesses from .032" to .250"

(.813 to 6.35 mm).

36" lengths standard.

|

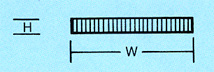

Strip Gasketing

In

solid or sponge type silicone.

Standard widths from .093" to .750"

(2.36

to 19.05 mm).

Standard heights from .062" to .312"

(1.57 to 7.92

mm).

Strips can be bonded together

with standard non-conductive silicone

adhesive. |

|

|

Material Specifications:

Elastomers:

Solid silicone: ZZ-R-765, Class 2b, Grade 40, Color gray,

Temperature Range : -80F to 425F

Silicon sponge: AMS 3195, Color gray, Temperature Range : -80F to

400F

Fluorisilicone: MIL-R-25988B, Type II, Class 1, Grade 40, Color

blue, Temperature Range : -90F to 400F

Wire:

Monel wire: QQ-N-281, Class A, .004" dia.

Aluminum wire: AMS 4182, Alloy 5056, .005" dia.

How to

Order Sheet Material

Sheet gasketing material is identified by

an 8-digit part number (XXXX-XXXX).

To order:

1. Select the first 4 digits from the following

list:

- 1213-XXXX Solid

silicone, Monel wires

- 1313-XXXX Sponge

silicone, Monel wires

- 1443-XXXX Solid

fluorosilicone, Monel wires

- 1223-XXXX Solid

silicone, aluminum wires

- 1323-XXXX Sponge

silicone, aluminum wires

- 1453-XXXX Solid

fluorosilicone, aluminum wires

NOTE: For

pressure-sensitive adhesive (PSA) backing,

substitute 7 as the second digit (1713) for solid

silicone; 8 as the second digit (1823) for sponge.

2. Select height and width from the Sheet

Identification and P/N Selection Chart shown below.

Replace the first 2 digits of the second series

with the height in decimal inches and the second 2

digits with the width, also in decimal inches. Do

not use metric dimensions to order.

Example:

To order solid silicone sheet, Monel wires, .062"

thick by 3" wide;

order 1213-0630.

Example:

To order sponge silicone sheet, Monel wires, .250"

thick by 6" wide with PSA back; order 1813-2560.

Shielding Express

will assign part numbers to custom orders. |

|

Sheet

Identification &

P/N Selection Chart

30 Durometer |

|

Height |

Solid Silicone |

Sponge Silicone |

|

.032" (.81 mm) |

X |

- |

|

.045" (1.13 mm) |

X |

- |

|

.055" (1.38 mm) |

X |

- |

|

.062" (1.57 mm) |

X |

- |

|

.094" (2.40 mm) |

X |

X |

|

.125" (3.18 mm) |

X |

X |

|

.156" (3.96 mm) |

X |

X |

|

.188" (4.78 mm) |

X |

X |

|

.250" (6.35 mm) |

X |

X |

|

Width |

Solid Silicone |

Sponge Silicone |

|

3.00" (76.20 mm) |

X |

X |

|

4.50" (114.30 mm) |

X |

X |

|

6.00" (152.40 mm) |

X |

X |

|

9.00" (228.60 mm) |

X |

X |

|

|

|

How to

Order Strip Material

Multi-Point I

strip gasketing material is identified by a 8-digit

part number (XXXX-XXXX).

To order:

1. Select the first 4 digits from the following

list:

- 1212-XXXX Solid

silicone, Monel wires

- 1312-XXXX Sponge

silicone, Monel wires

- 1412-XXXX Solid

fluorosilicone, Monel wires

- 1222-XXXX Solid

silicone, aluminum wires

- 1322-XXXX Sponge

silicone, aluminum wires

- 1422-XXXX Solid

fluorosilicone, aluminum wires

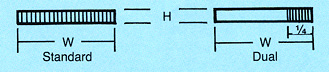

- 1217-XXXXSolid

silicone, dual configuration

- 1317-XXXX Sponge

silicone, dual configuration

- 1417-XXXX Solid

fluorosilicone, dual configuration

2. Select height

and width from the Strip Identification and P/N

Selection Chart shown below. Replace the first 2

digits of the second series with the height in

decimal inches and the last 2 digits with the

width, also in decimal inches. Do not use metric

dimensions to order

Example:

To order solid silicone strip, Monel wires, .125"

high by .500" wide;

order 1212-1250

Example:

To order solid silicone strip, dual configuration,

.093" high by.312" wide;

order 1217-0931.

Shielding Express will assign part numbers to

custom orders. |

|

Strip

Identification &

P/N Selection Chart

30 Durometer |

|

Height |

Solid Silicone |

Sponge Silicone |

|

.062" (1.57 mm) |

X |

- |

|

.093" (2.36 mm) |

X |

X |

|

.125" (3.18 mm) |

X |

X |

|

.188" (4.78 mm) |

X |

X |

|

.250" (6.35 mm) |

X |

X |

|

.312" (7.92 mm) |

X |

X |

|

Width |

Solid Silicone |

Sponge Silicone |

|

.093" (2.36 mm) |

X |

X |

|

1.25" (3.18 mm) |

X |

X |

|

.188" (4.78 mm) |

X |

X |

|

.250" (6.35 mm) |

X |

X |

|

.312" (7.92 mm) |

X |

X |

|

.375" (9.53 mm) |

X |

X |

|

.500" (12.70 mm) |

X |

X |

|

Dual

configuration, with wires in one-quarter area of

section, available in either solid or sponge

silicone in all above standard heights with

standard widths of .500" (12.70 mm), .625" (15.88

mm) and .750" (19.05 mm). |

|

|

|

Product Categories

I

Shielded Optical Windows I

I Oriented Wire Shield and Seal I

Foil Shield and Seal I

I Woven

Shield and Seal

I Thermally

Conductive Materials I

I

Frame Shield I Knit

Shield I

Knit Shield and Seal I

Knit Shield Wrap I

I

Particle Filled Conductive Silicone Gasketing I

Shielded Air Ventilation Panels I

I Shielded

Screen Filter Ventilation Panels I Conductive

Caulking & Adhesives

I

I

Knit Shield Ring and Contact Buttons

I

|